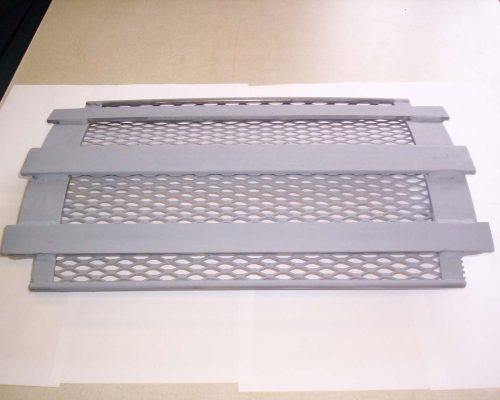

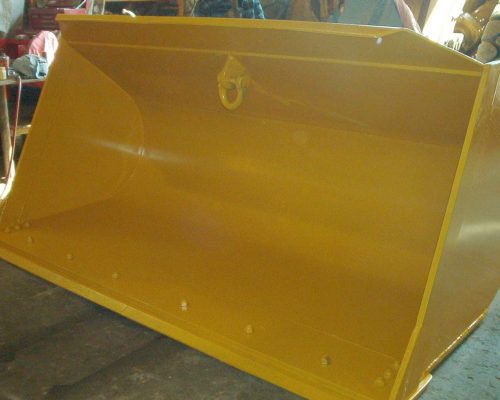

We are capable of fabricating a variety of structures per designs supplied by our customers.

Staffed by skilled trades personnel, we are equipped to work with carbon and stainless steels as well as aluminum. Our MIG and TIG welding services, CNC profile cutting capabilities & in-house material inventory allow us to produce quality work with fast turnaround. Dual overhead cranes, forklifts and material handling expertise enable us to tackle projects of significant size. For outside processes such as powdercoating, galvanizing & non-destructive testing, we retain the services of reputable vendors to ensure each job is done right.

What we can do:

We also have the following capabilities:

- OFW/Brazing (Oxy-Fuel Welding)

- OFC (Oxy-Fuel Cutting), CNC and Conventional

- PAC (Plasma Arc Cutting), CNC and Conventional

- PAG (Plasma Arc Gouging)

- ACAG (Air Carbon Arc Gouging)

- Bandsaw

- Shearing

- Bending

- Punching

Customers have approached us to fabricate items such as:

- Presses

- Rail Cars

- Racks

- Roof Access Ladders

- Custom plate profile designs

We are capable of the following processes:

- SMAW (Shielded Metal Arc Welding)

- GMAW (Gas Metal Arc Welding)

- MCAW (Metal-Cored Arc Welding)

- FCAW (Flux-Cored Arc Welding)

- GTAW (Gas Tungsten Arc Welding)

Equipment

Welders:

- Lincoln 256 Power Mig

- ESAB Migmaster 250 PRO

- ESAB Mig 4002c

- Miller Deltaweld 452

- Miller Syncrowave 180 SD

- Hobart Mega Arc 400

Material Cutting:

- Burn Table (ESAB Falcon FXA-3000, with a capacity of 72" x 144" and capable of cutting steel up to 6" thick)

- Plasma cutter, manual (Hypertherm Powermax)

- Horizontal & vertical bandsaws

Other:

- Ironworker (Scotchman 6509, with 65-ton capacity)

- Hydraulic presses of various sizes and orientations, and capacities from 25 to 100 ton

- Dual overhead cranes, each with 5-ton capacity

- Two forklifts; one with capacity of up to 18,000 lbs